wenzhou ouwei technology co.,ltd

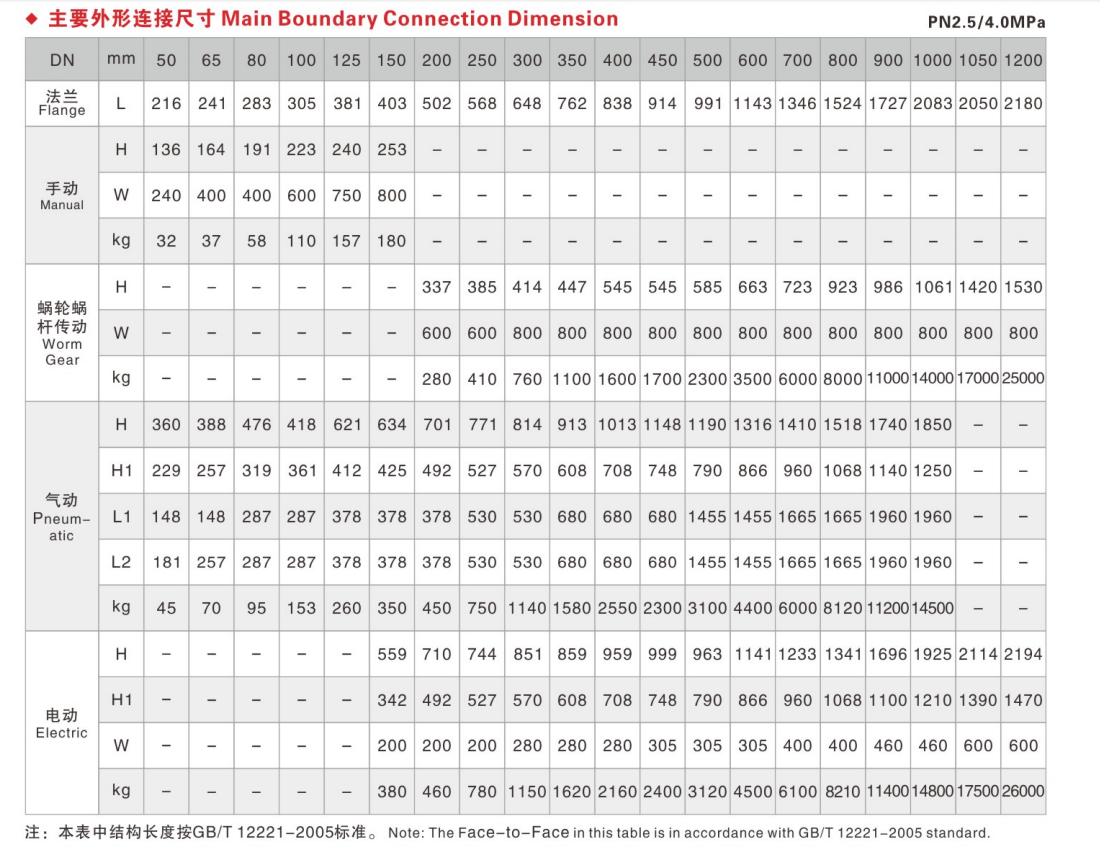

OUWEI WEAR-RESISTANT BALL VALVE PN1.6MPa PN2.5MPa PN4.0MPa PN6.4MPa PN10MPa PN15MPa PN25MPa PN42MPa

OUWEI WEAR-RESISTANT BALL VALVE PN1.6MPa PN2.5MPa PN4.0MPa PN6.4MPa PN10MPa PN15MPa PN25MPa PN42MPa

Compartir

◆Reliable Seal Design Features

The sphere is made of forged material and its surface is chemically treated.it can be sprayed and welded with nickel-phosphorous alloy,tungsten carbide and chromium carbide according to customer's requirements, and its finish reaches the mirror effect.The valve is of zero-leakage structure of soft and hard double seal, which ensures effective cut-of of the pipeline at the downstream end.The soft seal adopts enhanced ptfe, with low friction coefficient, high structural density and excellent self-lubrication performance. The hard seal is treated by spray welding nickel-phosphorous ally, tungsten carbide and chromium carbide, with a smooth finish up to the mirror surface and a small friction coefficient with sphere.

Considering the metal particles in the medium influence on zero leak sealing, sphere of PTFE or rubber seal as the primary sealing, sphere of metal valve seat seal as secondary seal, and to prevent foreign body in pipeline into the seat and the elastic device cause damage to the seat the seat is equipped with double sealing, can ensure the impurities in the seat and the elastic device, greatly lengthen the service life of the valve. At the same time, the seat is equipped with emergency sealant injection system, which can obtain temporary sealing requirements.

◆Fire Prevention/Anti-Static Structure

Valve structure for fire safety. Once the rubber or tetrafluoron sealing ring is burned or softened,the metal seat can still fit the ball effectively under the media pressure and spring force, and play a sealing role, which conforms to the requirements of fire resistance test.The ball is in contact with the non-metallic material of the valve seat,and the friction between the ball and the valve seat may generate static electricity, The static electricity generated on the ball is transmitted to the valve body through the stem through the anti-static structure. so as to eliminate the accumulation of static electricity.

◆ Stem Blowout Proof Design

The heat treated high strength, high quality stem and ball precisely fit,and at the stem with blowout design, can prevent abnormal cases of stem fly out, so as to effectively avoid the occurrence of such safety accidents.

◆Piston Effect Seat Design

inlet and outlet valve seats are designed with symmetrical bi-directional sealing. This piston type self-sealing structure of medium can be designed as "single piston effect" pressure self-releasing sealing seat structure and"double piston effect" double sealing structure according o customer needs. Single piston effect means that when the pressure of the middle chamber is are after than that of the upstream and downstream pipelines, the valve seat at the outlet end automatically pushes away, and the pressure of the cavity automatically drains to the downstream pipeline.

Double piston effect means that when the pressure of the chamber is greater than the pressure of the downstream pipeline, the inlet end and outlet end can maintain the seal at the same time, but when the pressure of the middle chamber exceeds 1.33 times of the corresponding pressure value of the pressure class, the pressure will be discharged through the automatic safety relief valve of the middle chamber